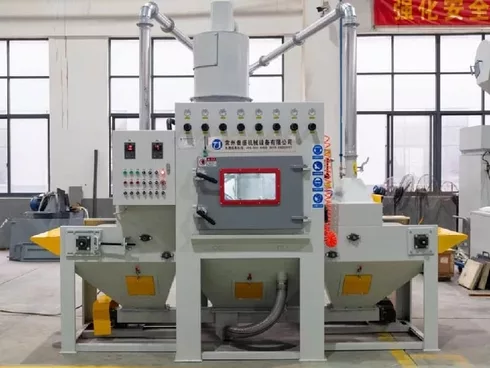

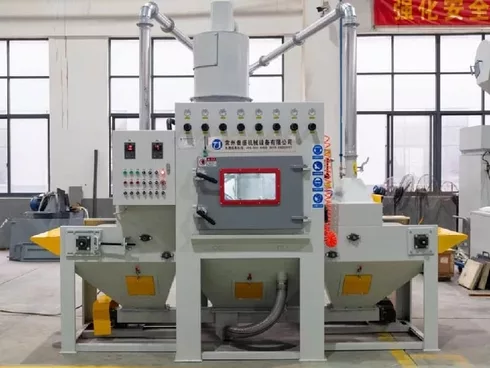

Pass-thru Sandblaster

Parts moves on a belt through a blasting chamber for surface treatment.

Automate your sandblasting process for faster production, consistent results, and reduced labor costs. Ideal for large-scale operations.

Parts moves on a belt through a blasting chamber for surface treatment.

Parts rotate via several blasting stations for surface treatment.

Parts rotate in a perforated basket while abrasive media blasts for uniform surface treatment.

Parts tumble on a conveyor belt while blasting media ensures even cleaning or finishing.

Parts rotate on a turntable while blasting media ensures even surface treatment for precise finishing.

The machine automatically blasts pipe thread ends, ensuring uniform cleaning and surface preparation for threading.

Parts rotate on a turntable while abrasive media blasts, ensuring even cleaning for mold surfaces.

Screw rotates while the nozzle moving and abrasive media blasting, ensuring even cleaning.

Upgrade your surface treatment process with our high-precision automatic sandblasting machines. Achieve faster, consistent results with minimal manual effort.

Automatic sandblasting machines deliver high-precision surface treatment, reduce labor, and improve safety, offering reliable and cost-effective performance for large-scale operations.

Fully automated system for continuous and consistent sandblasting, minimizing manual labor.

Built with durable, high-quality materials to withstand harsh working environments and extended use.

Capable of handling various workpiece sizes, shapes, and materials with interchangeable nozzles.

Customizable pressure, speed, and nozzle configurations to suit different materials and surface finishes.

Integrated dust collection system to maintain a clean working environment and reduce airborne contaminants.

Designed to optimize energy use, reducing operational costs over time.

Explore our gallery to see the precision, efficiency, and power of our automatic sandblasting machines. View real-life applications, close-ups of the machinery, and finished surfaces to experience the quality and performance firsthand.

Experience the power of our innovative solutions designed to boost efficiency, ensure top-quality results, and provide reliable support. Whether you’re tackling large-scale projects or seeking precision for smaller tasks, we offer the tools and expertise to help you succeed.

Boost Efficiency: Our solutions streamline your workflow, helping you complete projects faster and more effectively.

Ensure Quality: We deliver top-tier results with precision tools and equipment that meet the highest standards.

Reliable Support: Count on our expert team to provide guidance and assistance, ensuring seamless operations every step of the way.

Discover what our clients have to sya

The machine automates the sandblasting process by using a conveyor system or robotic arms to move parts through the blasting chamber, ensuring consistent and efficient surface treatment.

The automatic sandblasting machine is suitable for various materials, including metal, glass, ceramics, plastics, and more, depending on the abrasive media used.

No, the machine is designed for easy maintenance. Regular cleaning and inspection of key components will keep it operating efficiently.

These machines are widely used in industries such as automotive, aerospace, electronics, construction, and manufacturing, where surface treatment and preparation are critical.