Tumblast Machine

Tumble belt shot blast machines efficiently clean and finish small parts by tumbling them for uniform treatment.

Shot blasting and sandblast machines are critical for the automotive industry, providing efficient cleaning, deburring, and surface preparation for a wide range of components. From small parts like bolts and gears to large components like chassis and engine blocks, these machines deliver precise and consistent surface treatment. By removing rust, scale, and other contaminants, shot blasting machines ensure optimal surface quality, enhancing the performance and durability of automotive parts. Perfect for high-volume production and complex shapes, these machines help streamline manufacturing processes and improve product quality.

it removes the residual sand in the sand casting cavity, and also removes the burrs and flash on the workpiece surface, providing good surface accuracy for subsequent machining.

mainly used to clean the burrs on the surface of aluminum die castings, which greatly improves the appearance quality of the product and provides a good surface effect for the next process.

The sandblasting process strengthens the piston rod by inducing compressive stress, which improves its resistance to wear and fatigue over time.

Efficiently cleans and maintains automotive parts, ensuring longer life and consistent, high-quality production results.

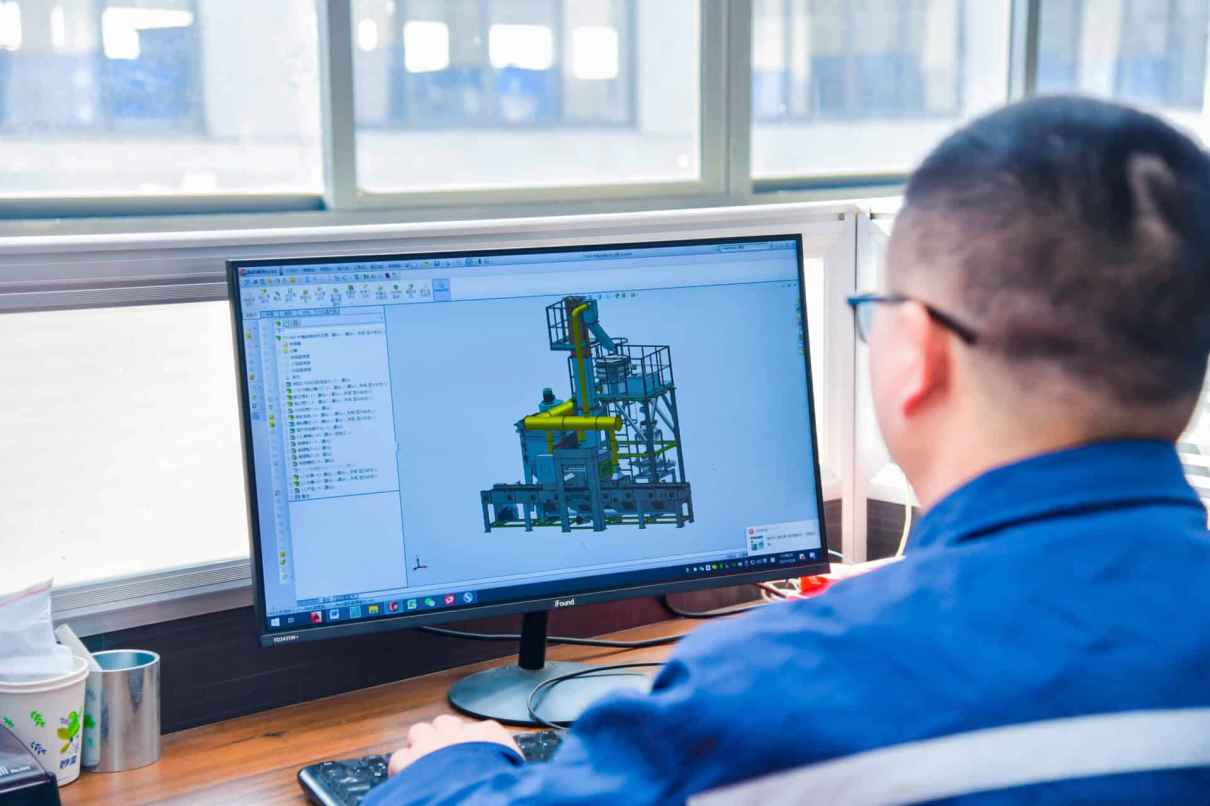

Our experienced technician team is here to guide you in selecting the right shot or sand blasting machine for your specific products. With years of industry knowledge and hands-on expertise, we assess your production needs, material type, and finishing requirements to recommend the ideal solution. Whether you're working with complex parts or high-volume production, we ensure you get the most efficient and effective machine for your operations, enhancing productivity and delivering superior results.

This helps us recommend the right machine for the job.

Different materials require specific blasting media and machine settings.

This allows us to select a machine that matches your production capacity.

This depends on your production flow and efficiency goals.